Rolling mill line suitable for the production of copper and aluminium flat wires

Products > Rolling mill line suitable for the production of copper and aluminium flat wires

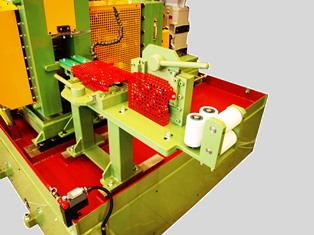

Plant composition:

– Cantilever Pay-off for reels DIN 1000/1250 with a maximum weight of 2000kg.

– Wire Straightener machine composed with 5+5 hardened and grinded steel rollers.

– The Rolling mill line has 3 rolling cages with cylinders Ø 180mm and working area of 100mm.

– The Cylinders are made in treated steel “ completely hardened”, and the minimum hardness surface is of 63Hrc, the internal hardness are min. 50Hrc.

Between the 3 rolling heads there are 2 flanging idle for the calibration of the width flat.

Dimensional control on 2 axis.

– Take-up suitable for bobbins (DIN 1000) with maximum weight 2.000Kg, the take up is placed on a translation unit that allows the stratification of the wires.

English

English  Italiano

Italiano